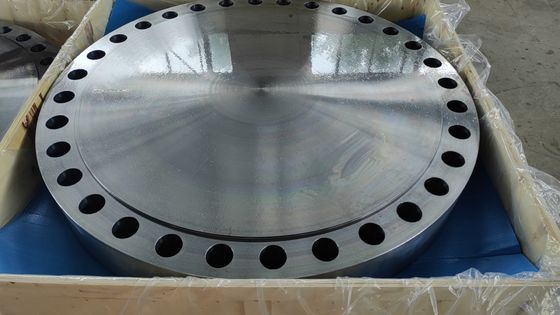

높은 안전 범위 합금 강철 플랜지 ANSI B16.5 DN80 150급

1제품 설명

합금강 플랜지 (Alloy Steel Flange) 는 합금강으로 만든 파이프 부품으로 파이프, 밸브, 펌프, 압력 용기 및 기타 장비를 연결하여 완전한 파이프 시스템을 형성합니다.,밀폐되고 압력 지탱 연결 포인트는 두 개의 플랜지 표면을 볼트와 그 사이에 가착으로 고정하여 고정됩니다.그리고 극한의 운영 조건, 전력 생산, 석유화학, 석유 및 가스와 같은 중공업의 중요한 기초 구성 요소가됩니다.

2주요 제품 매개 변수

재료 등급: ASTM A182 F11 (1.25Cr-0.5Mo), F22 (2.25Cr-1.0Mo), F91 (9Cr-1.0Mo-V), A350 LF2 (저온 서비스용) 등

압력급:

ASME 표준: 클래스 150, 300, 600, 900, 1500, 2500

EN/GB 표준: PN6, PN10, PN16, PN25, PN40, PN64, PN100

명목 지름:

ASME 표준: NPS 1/2"에서 24" (ASME B16.5), 26"에서 60" (ASME B16.47).

EN/GB 표준: DN15에서 DN600 이상

표면형: 윗면 (RF), 평면 (FF), 고리형 관절 (RTJ), 남성과 여성 (M/F), 혀와 굴 (T/G).

제조 표준: ASME B16.5, ASME B16.47, EN 1092-1, GB/T 9112~9124, 등

연결 유형: 웰드 넥 (WN), 슬립 온 (SO), 소켓 웰드 (SW), 스레드 (Thd), 블라인드 (BL) 등

3제품 장점

뛰어난 기계적 특성: 합금 원소 (크롬, 몰리브덴, 바나디움 등) 는 더 높은 강도, 강도 및 미끄러지기 저항을 제공합니다.

우수한 고온 압력 저항: 고온에서 높은 강도를 유지하고 변형이나 파열에 저항합니다.

우수한 경화 및 산화 저항성: 특히 경화 매체 또는 고온 산화와 관련된 서비스에 적합합니다.

장수기: 올바른 선택과 설치로 수십 년 동안 안정적으로 작동 할 수 있으며, 소유 비용도 줄일 수 있습니다.

높은 안전성 및 신뢰성: 국제 표준을 엄격히 준수하여 제조 및 검사하여 극단적인 조건 하에서 시스템 안전성을 보장합니다.

높은 안전 범위 합금 강철 플랜지 ANSI B16.5 DN80 150급

|

항목

|

가치

|

|

원산지

|

중국

|

|

|

상하이

|

|

브랜드 이름

|

토보

|

|

모델 번호

|

인콜로이800

|

|

이름

|

금속

|

|

소재

|

합금강 A234 WP 1급

|

|

종류

|

WN

|

|

색상

|

자연

|

|

형태

|

둥근 모양

|

|

MOQ

|

1개

|

|

크기

|

맞춤형

|

|

압력

|

300# 1500#

|

|

제품 이름

|

]연금강 플랜지

|

|

표면

|

고객

|

1당신은 무역회사인가요, 제조사인가요?

우리는 제조업체입니다. 알리바바 인증서를 볼 수 있습니다.

2배송시간은 얼마인가요?

일반적으로 상품이 재고에 있는 경우 5-10일입니다. 또는 상품이 재고에 없는 경우 15-20일입니다. 양에 따라입니다.

3샘플을 제공하시나요?

예, 우리는 무료로 샘플을 제공 할 수 있지만 화물 비용을 지불해야합니다.

4지불 조건은 뭐죠?

지불 <=1000USD, 100% 사전. 지불>=1000USD, 50% T/T 사전, 출하 전에 잔액.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!